Product

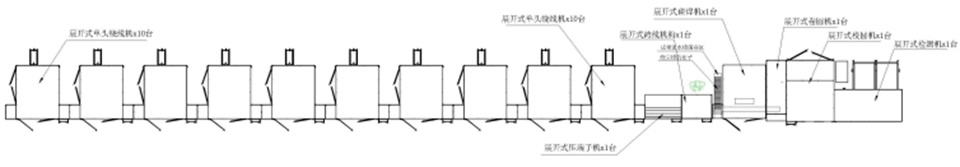

Fully automatic BLDC motor stator production line 3.0

Category:

Fully automatic stator/rotor production line

Key words:

Summary:

Fully automatic operation of the brushless motor winding machine: ① The equipment automatically winds the wire and wraps the wire end around the terminal block -- ② The wire is manually inspected by the semi-automatic wire crossing machine, and the wound iron core is placed on the cache assembly line

E-mail:

Product Parameters

Fully automated homework:

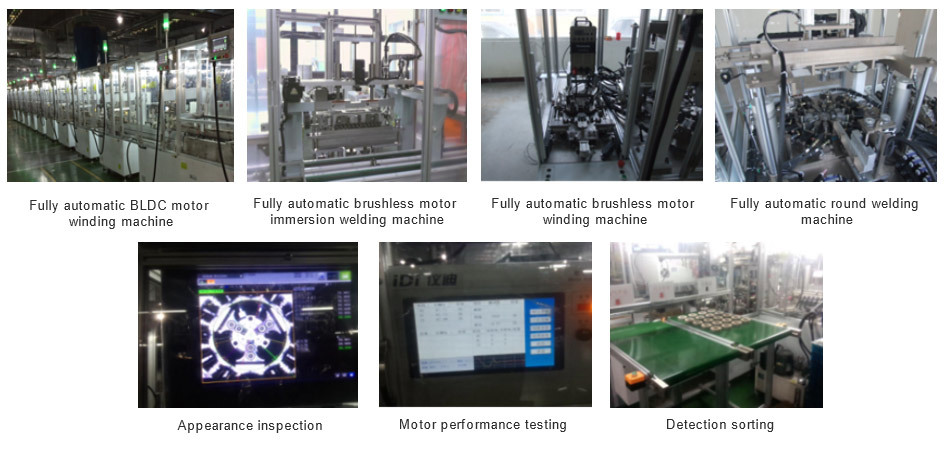

① The equipment automatically winds the wire and wraps the wire ends around the wiring terminals. ② The iron core after winding is manually inspected by a semi-automatic wire crossing machine and placed on the buffering assembly line. ③ The fully automatic immersion welding machine automatically immerses/bumps the terminals. ④ The equipment automatically rolls round. ⑤ The equipment automatically calibrates and welds. ⑥ The equipment automatically detects (external dimensions, motor performance, etc.). ⑦ The equipment automatically sorts out good and bad products

Production capacity: 120000 units/month (calculated based on L7.5, wire diameter 0.28580 turns)

Working hours: fully automated homework 22H, 26 days

Iron core form: unfolded, 6 slots, 9 slots, 12 slots, 15 slots, 18 slots

Scope of application: Wire diameter Max 0.46mm, core length Max 330mm, core outer diameter 105mm, stack thickness Max 50mm

Product Inquiry

ZTD Technology Industry(Qingdao)Co.,LTD

Contact Us

Tel: +86-0532-58661866 / 58661278

Mobile phone: +86-15215321423 / 15953263266

Address: No. 187, Jinshui Road, Lisong District, Qingdao, Shandong, China

Mobile Website

Copyright © 2024 ZTD Technology Industry(Qingdao)Co.,LTD | SEO | Business License